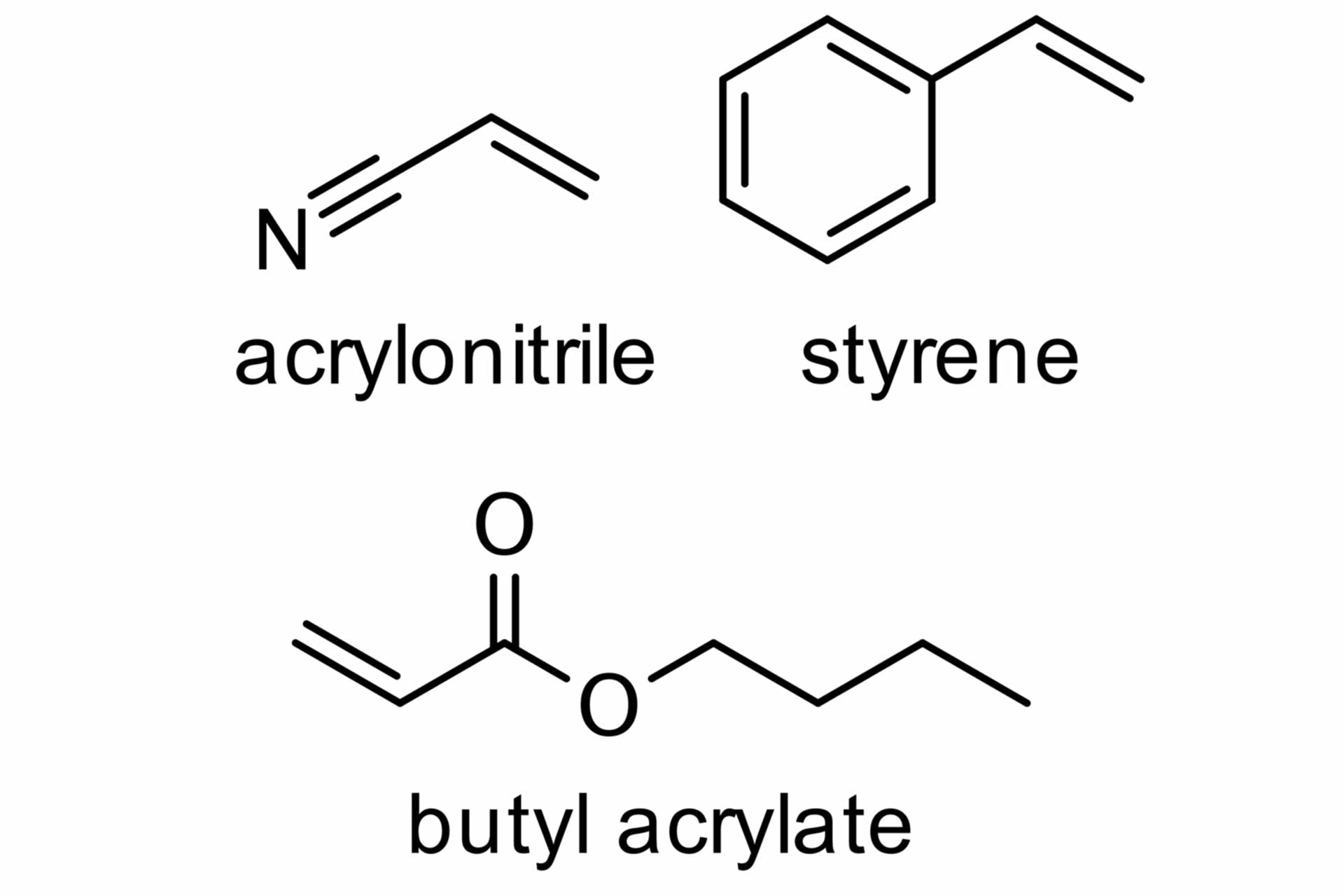

ASA stands for acrylonitrile styrene acrylate, which is a graft copolymer of acrylic ester, acrylonitrile, and styrene. The outer layer is composed of grafted polystyrene acrylonitrile copolymer, abbreviated as SAN, and the core of the copolymer is butyl polyacrylate rubber, abbreviated as PBA.

ASA has strong resistance to ultraviolet (UV) radiation. It is suitable for outdoor injection molded products that are exposed to direct sunlight, keeping products from getting yellow.

The four major advantages of ASA:

- Mechanical and physical properties: ASA has excellent mechanical and physical properties.

- Weathering resistance: ASA has strong weather resistance.

- High temperature resistance: ASA performs well under high temperature conditions.

- Antistatic performance: ASA, as an anti-static material, reduces the accumulation of dust on the surface.

Polymer materials with double bonds can be easily hurt by exposing to strong ultraviolet from sunlight. However, ASA solves this problem by replacing the unsaturated double bonds in ABS butadiene rubber with acrylic rubber lacking unsaturated double bonds. This substitute not only resists degradation, aging, and fading caused by UV exposure, but also provides strong protection against decomposition or discoloration caused by high temperatures during oxidation treatment in the atmosphere. Therefore, this significantly improves the aging resistance and weather resistance of the material.

According to the test results, the aging resistance of ASA is ten times stronger than ABS.